Together with the Peruvian farmers' cooperative Norandino, where our beans for the Awajun bar come from, we set up various projects to help the cocoa farmers. We are improving the infrastructure for fermenting the beans and planting new cocoa trees on degraded land. We are also building a chocolate factory together at the cooperative's site.

We do this together with Rabobank Foundation. Rabobank Foundation is providing a large part of the funding. To make this cooperation tangible, we have created a special bar for the Rabobank: The 'Norandino bar'.

Here the first bar will be handed over by Santiago Paz Lopez, director of the cooperative, to Pierre van Hedel, director of Rabobank Foundation.

This is Daan Kollmer (31). Industrial designer / Technician / Machine designer and builder.

This is Daan Kollmer (31). Industrial designer / Technician / Machine designer and builder.

What are you doing in the chocolate factory?

We are here in front of the 1930's roaster. A fantastic machine. Enver and Rodney bought it a while ago and have been getting it working ever since. My job was to get all the infrastructure between the different machines working, from electrical switch boxes to air exhaust pipes. And it worked! It's so cool to get such an old machine running again.

It is the big puzzle and the ingenuity of how to get all the machines working that is fun. I have installed the electricity and a number of parts and motors  must be replaced. This box contains the electricity of the burner. Quite complex. Yes, and it is quite exciting when you press the start button for the first time. The first time didn't go quite right...)

must be replaced. This box contains the electricity of the burner. Quite complex. Yes, and it is quite exciting when you press the start button for the first time. The first time didn't go quite right...)

What do you like about the chocolate factory?

What I like best here is the combination of high-tech machines and old stuff. It works well together here. And the delicious smell of chocolate!

What are you most proud of?

I am most proud of the mould feeder in combination with the cooling tunnel. This machine makes

harden the molds, which have just been filled with chocolate to cool, so that they can be removed from the molds. These machines were designed and made by me. Enver and Rodney clearly had an idea of what the machine should look like and what the machine should do. I can then go all out. Designing and then making; that's the best part!

harden the molds, which have just been filled with chocolate to cool, so that they can be removed from the molds. These machines were designed and made by me. Enver and Rodney clearly had an idea of what the machine should look like and what the machine should do. I can then go all out. Designing and then making; that's the best part!

What would you like to do in the future?

I have been in my business for 7 years now. I work in the food industry. I also work for the company that cuts the vegetables for Albert Heijn. But I have consciously or unconsciously moved more and more into the chocolate sector. I prefer to develop and make new machines in this sector. I think chocolate is a beautiful and fun product!

The most delicious bar

I am someone who loves dark chocolate, but the most delicious I think is the milk with salt bar!

Our friends the sausage makers Brandt & Levie make delicious sausages in a very nice way. Like the dry sausage Chipotle with our cocoa nibs in it. The most delicious sausage we have ever tasted!:-)

Photo credits: Brandt&Levie

The crowdfunding for the one and only chocolate factory is closed! And we can say that it has been an amazing success. More than 73,102 euros were invested, more than we had dared to dream. It's great to see that so many people are involved and are just as excited as we are about the realisation of a real chocolate factory.

We want to make more delicious, real chocolate and build a chocolate factory that you can visit. A place where everyone can come and see, feel, smell and experience the whole chocolate process, from bean to bar.

Crowdfunding was a logical step for us. "We can borrow money from big investors, but we believe much more in the power of the community. We like to share our success with all chocolate lovers and in this way remain as independent as possible".

We already have the place in Amsterdam, but we need more machines. A bigger burner, for example.

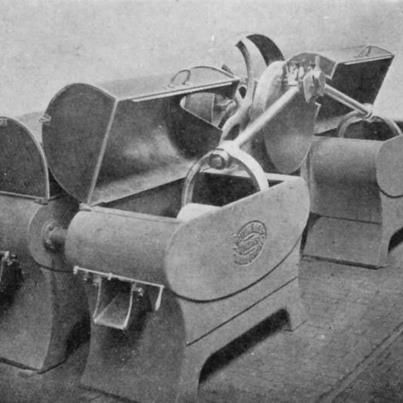

This is a 1930s ballroast. We bought it a year ago. A fantastic machine and perfect for the factory, but we still have to get it to work. And the rest of the machines that go with it, too, of course.

Now we can get down to business and of course we look forward to welcoming you to the chocolate factory! This will be 2017....

Joint venture deed

Another Milestone for the Chocolatemakers and the Norandino farmers' cooperative. Last month, we set up a joint venture with the Peruvian farmers' cooperative Norandino. Since 2013, we have been buying the cocoa beans they grow in the Amazon rainforest in north-east Peru. From this we make the 'Awajun 80%'.

The goal of this cooperation: building a chocolate factory in Peru for the local and international market. This will make it possible for the farmers to have direct access to the European market. The planning is to have this factory operational by the end of 2016.

DAM Prize winners 2014

Chocolatemakers is this year's winner of the Damprijs, the award for Amsterdam's most sustainable SME. After a complicated voting procedure, the small-scale chocolate factory from the north of Amsterdam emerged as the winner last night.

In its own words, the chocolate factory is the only one in the Netherlands to control all the links in the production chain, 'from cocoa farmer to bar'. That is no luxury in view of the exploitation that comes to light time and again in the chocolate production chain.

All the chocolate on Dutch supermarket shelves comes from just one factory in Belgium, from Barry Callebaut,' said Enver Loke of Chocolatemakers in his pitch for the Damprijs final last night. 'We want to show that it can be done differently.'

A first! Last Friday, we handed over the first Awajun bar to the Vice-President of Peru, Marisol Espinoza, the president of the cooperative and good friend Santiago, and of course to the man who makes the cocoa, Senor Rodriguez, who is also the chief of the Awajun Indians. The handover, which took place at the Hortus Botanicus in Amsterdam, was an emotional moment for the vice-president. The Awajun bar represents a highlight of her work in support of indigenous people and the preservation of nature. From January, this bar with 80% cocoa will be available through our webshop and various outlets. Keep an eye on our website and facebook for an update!

At the beginning of June, we made an appeal for help to unload the sailing ship Tres Hombres. This was not just a request, as there were 7 tonnes of cocoa beans and cocoa butter in the hold. And because not only the kilometres at sea count in sustainable transport, the cargo also had to be transported to the factory in a CO2-neutral way. With the help of your electric cars, carrier bicycles and even a shetland pony with a cart, the job was quickly done. You can see the photos here!

From this shipment of cocoa beans from the Dominican Republic, we have extended our range with the Tres Hombres 75% bar. This pure version of the Tres Hombres 40% bar contains roasted cocoa nibs for an extra taste sensation. The nib is the part of the cocoa bean which remains when the shell is removed from the bean. Cacao in its pure form; for all dark chocolate lovers.

Have you already tasted this bar? 30 Cent of each bar goes to the maintenance of the Tres Hombres and thus supports this sustainable form of trade transport. If you buy the bar at one of our outlets in Amsterdam, it will also be delivered by carrier cycle! Yep tissum!

Conching (rolling) is one of the crucial steps in the chocolate production process. This traditional process was discovered in 1879 by Rodolphe Lindt who, one evening, forgot to switch off his mixer. This created a mild chocolate mass that we still know today.

The machine that takes care of conching is called 'De Conche'. It is a mixing machine that is crucial for the preparation of chocolate! It ensures that the cocoa butter is evenly distributed in the chocolate and it improves the taste.

Conching is a long process and can take hours. Nowadays, the large chocolate processors no longer have the time for this, so they have developed machines that have reduced the conching process. Chocolatemakers does not want this! We go for chocolate with rich flavours!

Because 'De Conche' is no longer being made, we are now going to build this machine ourselves!

To be continued!